Products Overview

HOYA’s optical glass material and advanced tailor-made polish know-how is considered of hugely contributing to the following top three key functions of diffractive-grating-based waveguide:

①Big FOV; ②High brightness; ③Accurate light transfer

Image of light travelling through waveguide

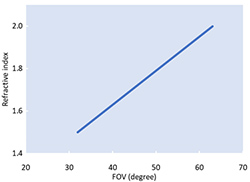

Big FOV

With outstanding high refractive index, various of HOYA’s optical glass makes bigger FOV waveguide design much easier and more flexible.

| Refractive index (nd) | 1.7~ | 1.8~ | 1.9~ | 2.0~ |

| Glass type ★Optical material & wafer for AR/MR waveguide |

E-FD1L | NBFD15-W FD60-W |

★FDS165-W ★FDS24-SW TAFD25 TAFD37A FDS16-W FDS18-W |

TAFD40-W TAFD55-W |

Image of FOV

(from waveguide principleangle)

Link between refractive index and FOV

High brightness

With high internal transmittance, HOYA’s optical glass contributes to less energy loss during lights (blue/green/red) travel through the waveguide, which leads to high brightness performance. As one general tradeoff of high refractive index material, the internal transmittance for blue (i.e. less than 500nm wavelength range) would be getting poorly lower, however, high internal transmittance even over blue range is HOYA AR/MR product’s outstanding feature.

Internal transmittance comparison between HOYA TAFD55-W

and other general high RI optical glass

Accurate light transfer

With HOYA’s advanced polish know-how, all wafer products delivered by HOYA could reach high surface quality, perfect TTV and excellent parallelism, which is considered as “must” key specifications for waveguide.

Available wafer dimensions/thickness for waveguide

| Dimension | Thickness |

| Φ150mm | 0.3~1.0mm |

| Φ200mm | 0.3~1.0mm |

| Φ300mm | 0.3~1.0mm |

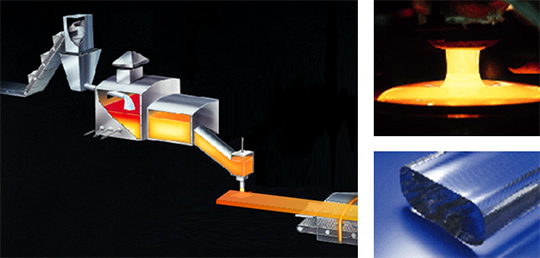

Good homogeneity & high internal quality

Melting processes for HOYA’s worldwide famous optical glass is also applied for producing high refractive index optical material for AR/MR industry, which makes HOYA’s high refractive index products optical glass to reach highest quality on optical glass level, with extremely high homogeneity and internal quality.

Melting processes for AR/MR optical glass

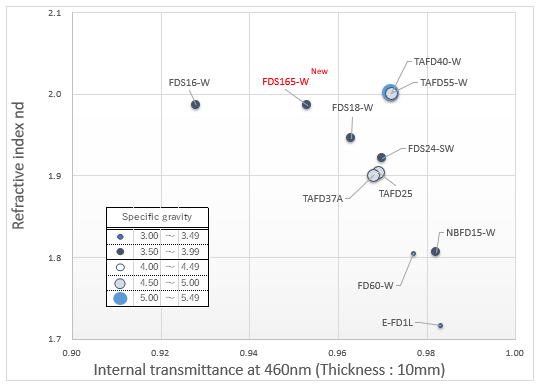

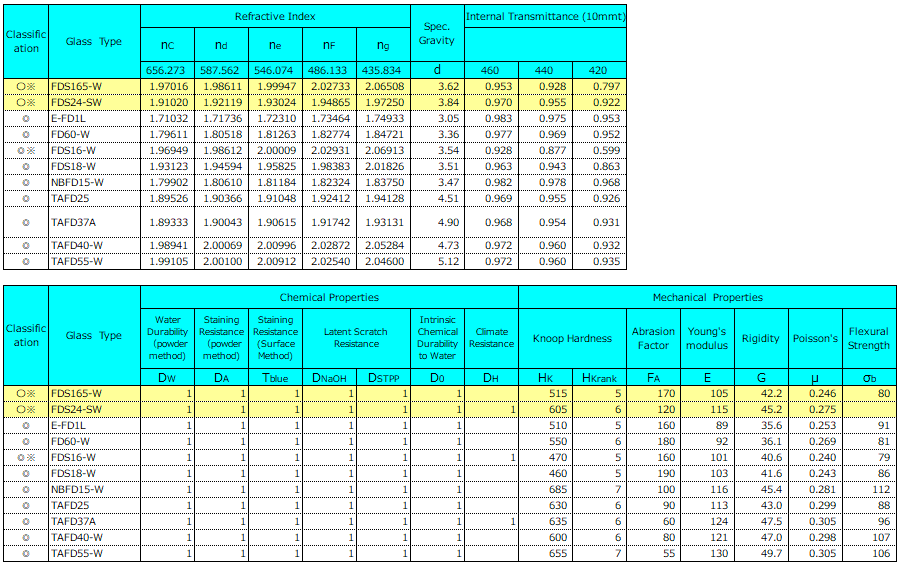

HOYA recommended optical glass products options

HOYA has considerably huge options of high-quality optical glass products, with various refractive index, internal transmittance, density and other parameters, to flexibly match AR/MR waveguide’s requirement.

Optical glass lineup for AR/MR waveguide with key parameters

* When a table is clicked, a table of a big picture is indicated.

Relationship between refractive index, internal transmittance, and

specific gravity of glass for AR/MR waveguides